Welding and metal fabrication are essential for building strong, durable, and custom metal structures. From creating everyday tools to large industrial projects, these processes shape the world around us.

Understanding welding and metal fabrication can help you see how raw materials turn into finished products. Whether it’s crafting a simple frame or a complex design, these techniques combine skill and precision to deliver incredible results.

Table Of Contents:

- Welding and Metal Fabrication: A Deep Dive

- How Huxley Design Excels in Welding and Metal Fabrication

- FAQs about Welding and Metal Fabrication

- Conclusion

Welding and Metal Fabrication: A Deep Dive

Welding joins metal pieces together using heat, and sometimes pressure. Metal fabrication is the broader process of creating sheet metal structures.

Fabrication includes cutting, bending, and assembling. Welding is often a crucial joining step. Safety equipment such as hearing protection is crucial when welding.

The Metal Fabrication Process

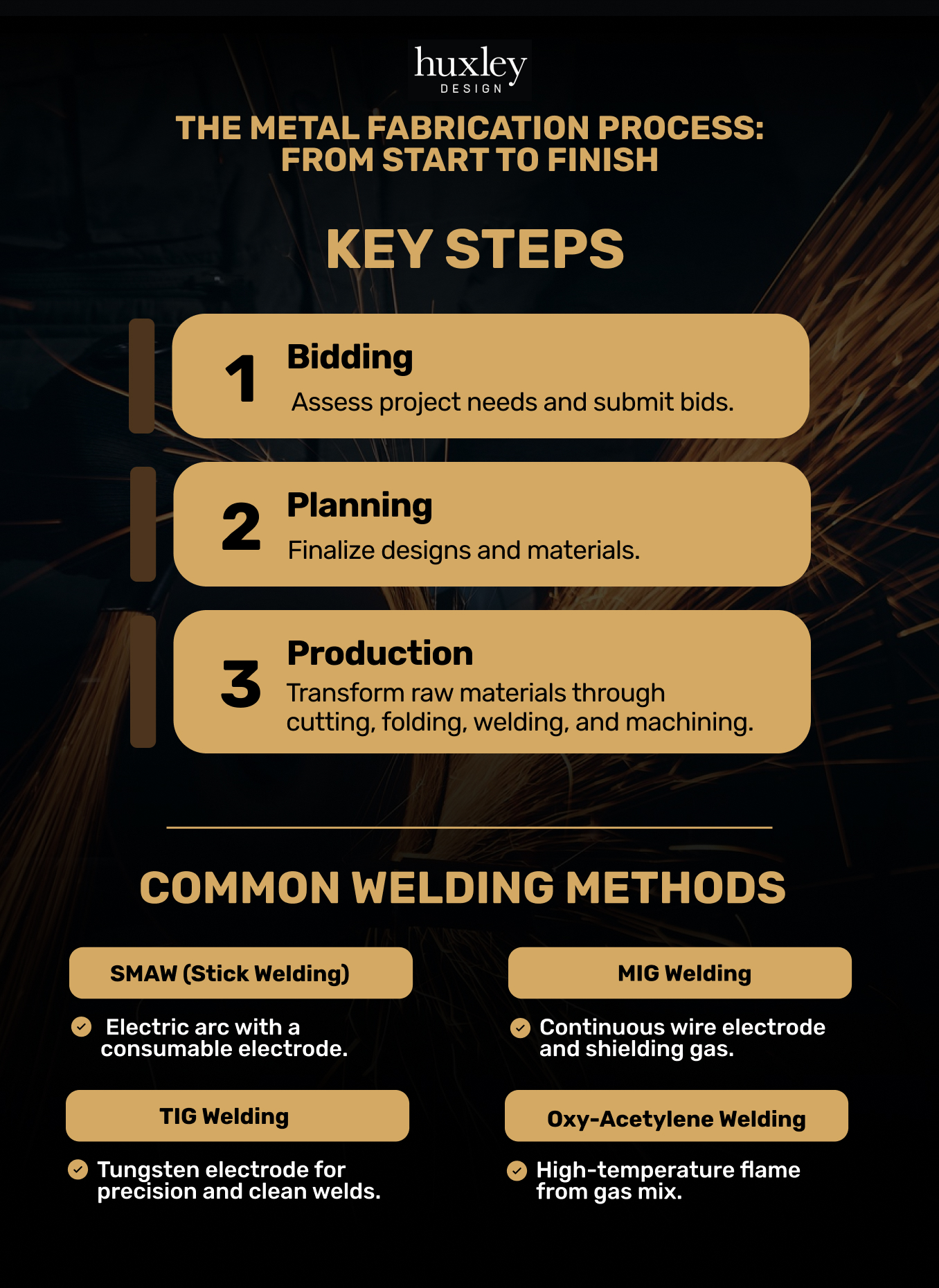

Metal fabrication follows a series of steps:

- Bidding: Companies assess project requirements and submit bids based on materials and processes.

- Planning: Detailed designs and material choices are finalized.

- Production: Raw materials are transformed into final products through various processes like cutting, folding, welding, and machining.

Metal cutting is an integral step. This entire fabrication process is vital to many different industries.

Common Welding Processes

Several welding techniques cater to different materials and project needs. The welding process varies based on the method and the material involved. Different welding methods require specific tools.

- Shielded Metal Arc Welding (SMAW), or stick welding, uses an electric arc and a consumable electrode. SMAW involves welding with a shielded metal arc.

- Gas Metal Arc Welding (GMAW), or MIG welding, uses a continuous wire electrode and a shielding gas. This is one of the most common welding processes.

- Gas Tungsten Arc Welding (GTAW), or TIG welding, employs a non-consumable tungsten electrode. It offers precise control and clean welds. GTAW is known as inert gas welding or tungsten inert gas welding.

- Oxy-acetylene Welding uses a mix of oxygen and acetylene to create a high-temperature flame. Gas welding requires different safety measures. This method involves joining metal with heat generated from a gas flame.

How Huxley Design Excels in Welding and Metal Fabrication

At Huxley Design, welding and metal fabrication are at the heart of what we do. We pride ourselves on delivering high-quality, customized sheet metal solutions that meet your unique needs. Our services are designed to make your vision come to life with precision, efficiency, and care.

What Sets Huxley Design Apart?

We approach every project with a dedication to quality and innovation. Here’s how we excel in welding and metal fabrication:

1. Advanced Equipment for Precision and Quality

- We use cutting-edge engineering technology, like fiber optic lasers, to ensure every cut and detail is precise and flawless.

- Our press brake machines allow us to bend and shape metal into intricate designs, ensuring your project’s structural integrity and aesthetic appeal.

2. Expertise in Welding Techniques

- Our skilled team specializes in MIG welding, which is ideal for steel, aluminum, and stainless steel. This ensures strong, durable bonds and a smooth finish for every project.

- We are well-versed in handling a variety of metals, allowing us to adapt to different project requirements effectively.

3. Comprehensive Metal Fabrication Services

We offer a full range of metal fabrication services to ensure your project is completed from start to finish under one roof:

- Design Assistance: Our team collaborates with you to create detailed designs that align with your goals.

- Laser Cutting: Precise and efficient cutting for all kinds of metal components.

- Powder Coating: A durable finish that protects your project while enhancing its appearance.

4. A Customer-Centric Approach

At Huxley Design, we believe in keeping you at the center of the process. Here’s how we make sure your experience is smooth:

- Consultation and Communication: We discuss your ideas and requirements, keeping you informed at every step of the project.

- Tailored Solutions: Every project is customized to meet your exact specifications, whether it’s for functional or decorative purposes.

- Timely Delivery: We respect your deadlines and ensure your project is completed on time without compromising quality.

How We Help with Welding and Metal Fabrication Projects

Whether you need a small component or a large, complex structure, we are equipped to handle projects of all sizes. Here’s what you can expect when you work with us:

From Concept to Completion

- Initial Consultation: We take the time to understand your needs, goals, and preferences.

- Detailed Design Process: Our team creates a blueprint that ensures accuracy and clarity before fabrication begins.

- Expert Fabrication: Using advanced equipment and skilled craftsmanship, we bring your designs to life.

- Finishing Touches: Our powder coating services provide protection and a polished look for your metal projects.

- Safe and Reliable Delivery: We ensure your finished product reaches you safely and is ready for use.

Why Choose Huxley Design for Your Welding and Metal Fabrication Needs?

We stand out because of our commitment to quality, precision, and customer satisfaction. Here’s why we are the right choice:

- State-of-the-Art Tools: Our advanced machinery allows us to deliver unmatched precision and efficiency.

- Experienced Team: Our skilled fabricators and welders bring years of experience and expertise to every project.

- Attention to Detail: From the smallest component to large-scale structures, we ensure every detail is perfect.

- Transparent Process: We maintain clear communication with you throughout the project to guarantee your satisfaction.

FAQs about Welding and Metal Fabrication

What is welding and metal fabrication?

Welding and metal fabrication involve creating structures and products from raw metal materials. Metal fabrication includes cutting, bending, and assembling metal pieces into desired forms. Welding is a technique used to join these metal parts together, ensuring strong and durable connections.

Is welding and fabrication a good career?

Yes, with steady job growth, high earning potential, and diverse applications it can be a rewarding path. The fabrication industry is constantly evolving. Many opportunities await skilled professionals in this field.

Is metal fabrication a good job?

Metal fabrication can be a good job for those who enjoy hands-on work. Creative problem-solving is also key. It is a rewarding career in metal manufacturing.

What is a metal fabricator welder?

A metal welder fabricator cuts, shapes, and joins metals. They create various products from metal parts to larger structures. It requires skill in welding techniques and operating fabrication tools.

These skills can be utilized in different metals fabrication projects.

Do you need a license to be a metal fabricator?

Generally, no license is required, though certifications boost credibility. This credibility enhances job prospects. For those in North Carolina, be sure to learn about requirements for a specific job.

Where can I find metal fabrication near me?

Huxley Design provides expert metal fabrication services to meet your local needs. From laser cutting to welding and powder coating, our skilled team ensures high-quality results for every project. Reach out to us for a custom quote and let us help bring your vision to life.

Conclusion

Welding and metal fabrication are transformative processes that turn raw materials into functional and beautiful structures. From intricate designs to large industrial components, these techniques combine precision, skill, and creativity to shape the world around us. Understanding these processes allows us to appreciate the craftsmanship behind everyday tools and architectural masterpieces.

At Huxley Design, we specialize in delivering exceptional welding and metal fabrication services tailored to your unique needs. With advanced equipment, skilled professionals, and a customer-focused approach, we are your trusted partner for bringing your vision to life. Contact us today to receive a personalized quote and let us help you build something extraordinary!

Recent Comments