Finding the right metal laser cutting services can feel overwhelming. With so many providers, how do you choose a service that fits your needs? This post explores metal laser cutting services, giving you the information you need to make smart decisions.

We’ll cover important factors like cost, material options, and turnaround times. We’ll also discuss finding a reputable provider and what questions to ask.

Table Of Contents:

- Understanding Metal Laser Cutting Services

- Choosing the Right Metal Laser Cutting Services

- Cost of Metal Laser Cutting Services

- Finding Reputable Metal Laser Cutting Service Providers

- Ensuring Quality and Precision with Metal Laser Cutting Services

- How Huxley Design Delivers High-Quality Metal Laser Cutting Services

- FAQs about Metal Laser Cutting Services

- Conclusion

Understanding Metal Laser Cutting Services

Metal laser cutting uses a high-powered laser to cut or engrave metal sheets and plates. This precise process is popular for various applications due to its speed, accuracy, and versatility. It allows for cutting different materials, like stainless steel, aluminum, and carbon fiber, and intricate cuts with smooth edges.

Benefits of Laser Cutting

Laser cutting offers key advantages: precision, speed, and versatility. It’s accurate and reduces waste with efficient nesting of cut parts.

Laser cutting is fast, giving your metal projects quick turnaround times. If you’re on a tight deadline and need sheet metal fabrication, laser cutting is a great solution.

Laser cutters are powerful and versatile. This allows for laser engraving, dimple forming, and hardware insertion on many metal types and thicknesses. They create custom metal parts quickly.

Applications of Metal Laser Cutting Services

Metal laser cutting services span many industries. Examples of those industries are automotive, aerospace, electronics, medical devices, and construction.

These industries use this technology in many ways, from car parts to medical innovations.

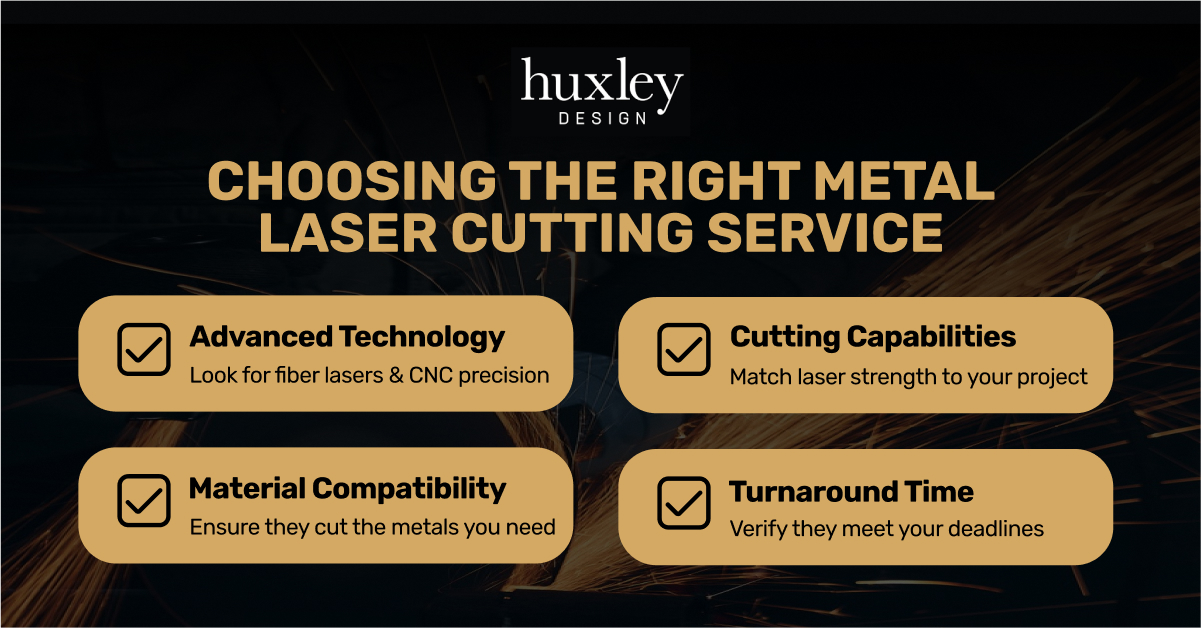

Choosing the Right Metal Laser Cutting Services

Choosing the best metal laser cutting services depends on several details. These details include material selection, budget, and order quantity.

Factors to Consider When Selecting a Service Provider

When considering metal laser cutting services, several factors stand out. These include modern machinery, fast turnaround times, and excellent quality.

First, look at the provider’s technology. Make sure they offer state-of-the-art laser cutting machines, such as fiber lasers, and CNC laser cutting capabilities for precise results. Having the best cutting machines will deliver superior quality of parts.

Second, check their available materials and thicknesses. Check the materials catalog of a provider before you get to involved in choosing them. Look to see what kinds of sheet metal they have.

Third, check laser cutters’ abilities and compare that with your project needs. Different laser strengths, like a 6000-watt laser, cut specific thicknesses. Some examples of steel cutting capacity, show varying thicknesses based on machine specs.

Make sure you find a metal cutting service near you with the right capabilities.

Fourth, understand that metal laser cutting turnaround times vary. Ensure the vendor’s workflow fits your deadlines.

Cost of Metal Laser Cutting Services

Pricing for metal laser cutting services involves several factors. Costs change based on project specifics. Review the pricing carefully to find out the actual costs.

Factors Affecting Pricing

| Factor | Impact on Price |

|---|---|

| Material Type | Different metals have different costs; steel differs from titanium. |

| Material Thickness | Thicker materials cost more due to increased cutting time and power. |

| Cutting Complexity | Intricate designs may be slightly more expensive due to additional laser passes. |

| Order Quantity | Larger orders can reduce per-piece costs due to distributed setup expenses. |

| Post-Processing Services | Services like powder coating, deburring, and bending increase prices. |

Get a grasp of typical metal laser cutting costs. Try shopping around for instant quotes from a reputable laser cutting and metal fabrication company. Look for reputable metal cutting near you if local is more convenient for you.

Finding Reputable Metal Laser Cutting Service Providers

When looking at metal laser cutting services, trustworthiness and positive reviews matter. This demonstrates reliability.

Where to Search: Metal Laser Cutting Services Near Me

Search online to find local providers. Many offer design services and CNC machining alongside cutting.

You can explore providers in your area. Another way to search locally is through search engine by entering phrases like “laser cutting services near me.”

Ensuring Quality and Precision with Metal Laser Cutting Services

Quality and tight tolerances are important when exploring metal laser cutting services. General tolerances apply for common orders, but there are often tighter tolerances that are possible, given correct order specs and setup. This applies even when working with templates for waterjet cutting.

Understanding Tolerances and Precision in Laser Cutting

Tolerances refer to the acceptable variance in final part dimensions. They are crucial in any precise laser cutting process. Make sure the tolerances are spelled out in a formal quote from your potential vendors.

You need tight tolerances for parts to fit together precisely, even on large-scale projects. DXF files are useful when submitting technical designs that must be held to strict standards. They provide a standard that is universally understood in design and fabrication fields.

Having proper laser cutting machines allows for precise design specifications to be followed accurately and precisely, delivering high-quality parts every time.

How Huxley Design Delivers High-Quality Metal Laser Cutting Services

At Huxley Design, we specialize in metal laser cutting services that provide industries with precise, custom-cut metal parts. Our advanced fiber optic laser technology ensures clean, accurate cuts, allowing us to create detailed designs and functional metal components. Whether for manufacturing, construction, or artistic projects, we make sure every piece is cut to perfection.

Our Expertise in Metal Laser Cutting

With years of experience in laser cutting, we understand that precision and efficiency matter. That’s why we use state-of-the-art fiber optic laser cutting machines to handle a variety of projects, from small custom jobs to large production runs. Our goal is to help industries get the exact metal parts they need with speed, accuracy, and quality.

What We Cut: Materials We Work With

We work with a range of metals to fit different industry needs, including:

- Steel – Durable and versatile, steel is used in many industries, from manufacturing to construction.

- Aluminum – Lightweight and resistant to rust, aluminum is perfect for applications where weight matters.

- Stainless Steel – Strong, corrosion-resistant, and visually appealing, stainless steel is great for both functional and decorative purposes.

Our laser cutting technology allows us to cut these materials into complex shapes, intricate patterns, or precise machine parts, ensuring each piece meets the highest standards.

How We Help Industries with Metal Laser Cutting

Our services support different industries by offering custom, high-quality metal parts that fit their specific needs.

- Manufacturing – We provide precisely cut components that help machines and products function smoothly.

- Construction – Our metal cutting capabilities allow for the production of structural components, brackets, and supports.

- Design & Art – We bring creative ideas to life by cutting detailed patterns and unique designs into metal.

FAQs about Metal Laser Cutting Services

How much do laser cutting services cost?

Laser cutting service costs vary based on factors like material type and thickness, complexity, order size, and post-processing services. Getting quotes from multiple providers is recommended.

How much does laser cutting cost?

Laser cutting prices depend on order details. Check with suppliers for up-to-date instant pricing. Factors affecting price may include surface finishes, order minimums for cart purchases, and general part complexity.

If you have designs ready you can often find instant online quotes with the submittal of proper cad files.

How much does a laser cut cost?

Laser cut prices depend on the job, order volume, and specific cutting task. Laser cutting machine power affects both speed and maximum material thickness, both impacting the ultimate job cost.

How thick of steel can a 6000 watt laser cut?

A 6000-watt laser typically cuts steel up to 1 inch thick, possibly more depending on the desired edge quality. This also depends on if the service uses a fiber laser cutting machine or another laser type. Surface finish may also affect the material that can be cut with specific machines.

Conclusion

Metal laser cutting services provide unmatched precision, speed, and versatility, making them essential for various industries, from manufacturing to design. Whether you need intricate patterns, durable structural components, or high-volume production, choosing the right provider ensures quality results and efficient turnaround times. By considering factors like technology, material compatibility, and expertise, businesses can make informed decisions and achieve outstanding results.

At Huxley Design, we take metal laser cutting to the next level with advanced fiber optic laser technology, ensuring clean, precise cuts for steel, aluminum, and stainless steel. Our commitment to quality, efficiency, and customization makes us the ideal partner for all your cutting needs.

Ready to experience the best metal laser cutting services? Contact us today!

Recent Comments