Metal fabrication demands skilled brake press operators. These professionals work with heavy machinery, shaping metal into various forms. Let’s explore their skills, knowledge, and career opportunities.

Brake press operators are essential to shaping the metal objects we use every day. From car parts to intricate designs, their precision and quality inspection bring our world to life. Consider the additional verification required sometimes, proving just how important their job is.

Table Of Contents:

- What is Metal Fabrication?

- What Does a Brake Press Operator Do?

- How Does a Brake Press Work?

- Why is the Brake Press Operator So Important?

- Skills and Qualities of a Successful Brake Press Operator

- Training and Career Path

- How We Ensure Quality at Huxley Design

- FAQs about Brake Press Operator

- What is a brake press operator?

- Is being a press brake operator a good job?

- Is a press brake hard to operate?

- What is the job description of a brake press operator?

- Where can I find a brake press operator near me?

- What qualifications do brake press operators have?

- What industries benefit from brake press operators and metal fabrication?

- Can I hire a brake press operator for my own business?

- What is the future of brake press operators with automation?

- Conclusion

What is Metal Fabrication?

Metal fabrication is the process of turning metal into different parts or products. It involves cutting, bending, and assembling pieces of metal into shapes that can be used for various purposes, from construction to automotive parts, and everything in between. Metal fabrication happens in many industries, and it requires precision and the right equipment to get things just right.

What Does a Brake Press Operator Do?

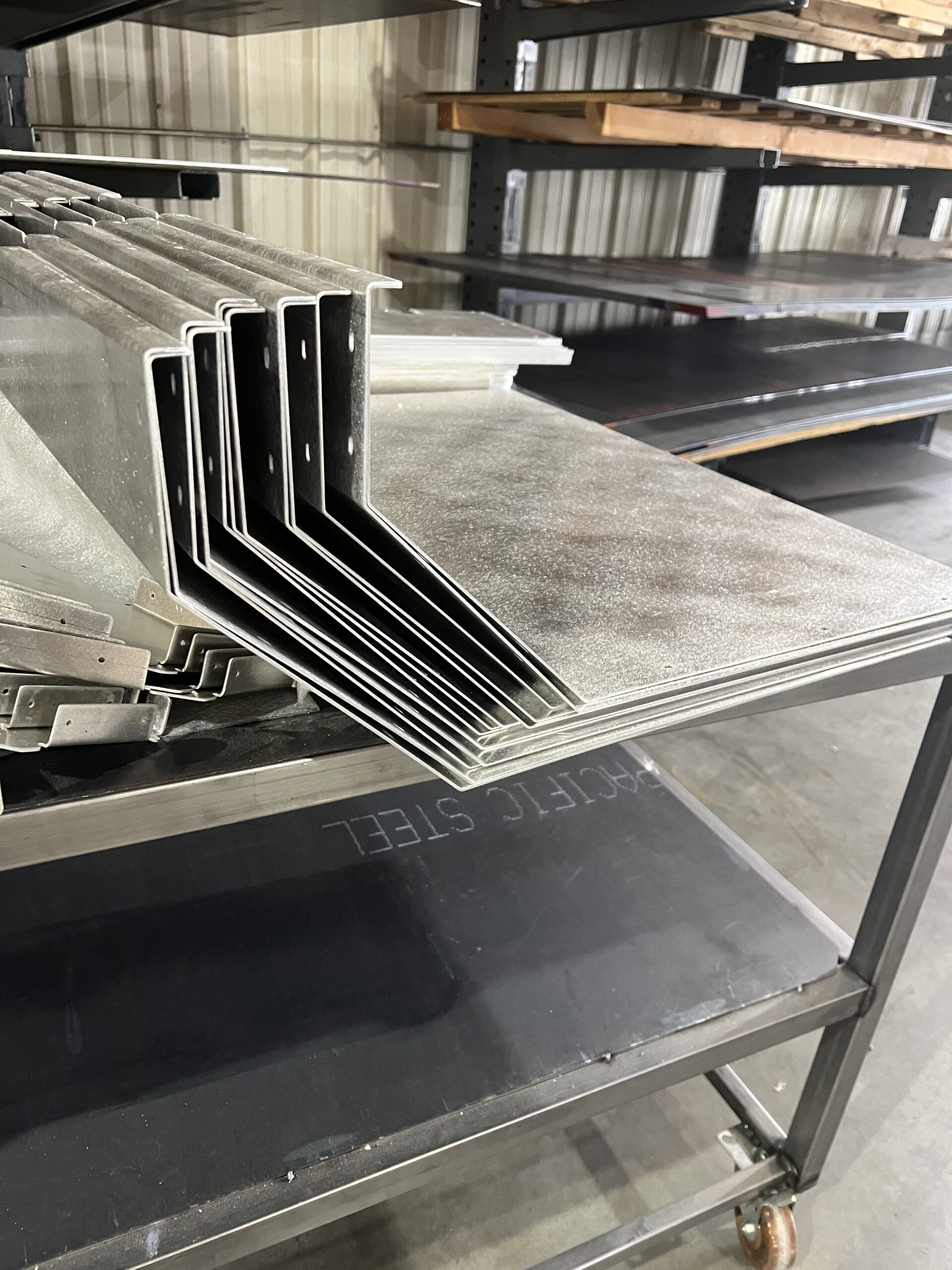

Brake press operators use a press brake machine for bending sheet metal. They follow blueprints and technical drawings while using computer numerical control (CNC) units. They account for different material types, like stainless steel and aluminum, understanding how each reacts to pressure.

Brake press operators are skilled in tooling and bending operations like air bending. They inspect finished products for quality control and handle basic machine maintenance.

How Does a Brake Press Work?

The brake press uses a combination of pressure and force to bend metal. The machine has two main parts: a punch and a die. The punch presses down on the metal, while the die holds it in place.

When the two meet, the metal bends to the desired shape. The brake press can handle different thicknesses of metal and can bend it in various ways. The operator must know how to adjust the machine for each specific job, choosing the right die, punch, and settings to get the perfect result.

Why is the Brake Press Operator So Important?

Without a skilled brake press operator, the metal fabrication process wouldn’t be as precise or efficient. The operator must make sure that the machine is set up correctly and that each bend is in the right spot. They must also be able to read blueprints or drawings to understand the exact specifications for each piece of metal.

In other words, brake press operators are like the hands of the metal fabrication process. They ensure everything is bent to the right angle and size, helping create parts that fit perfectly together.

Skills and Qualities of a Successful Brake Press Operator

Successful brake press operators need mechanical aptitude and problem-solving skills. Attention to detail ensures accurate bends and formations. Physical stamina and hand-eye coordination are necessary because brake press operation is physically demanding.

Reading technical and CAD drawings is essential. Good communication and teamwork skills are important. Adaptability is valued due to the continuous advancements in press brake technology.

Operators should stay up-to-date on the latest company reviews and be aware of any applicable privacy policies.

Training and Career Path

Most brake press operators start with a high school diploma or GED. Specialized training, such as vocational schools or apprenticeships, is becoming increasingly valuable.

On-the-job training is common, offering valuable experience and skill development.

Career advancement can involve specializing in complex setups or supervising a press brake department. CNC programming and tooling selection for bending operations also present growth opportunities.

How We Ensure Quality at Huxley Design

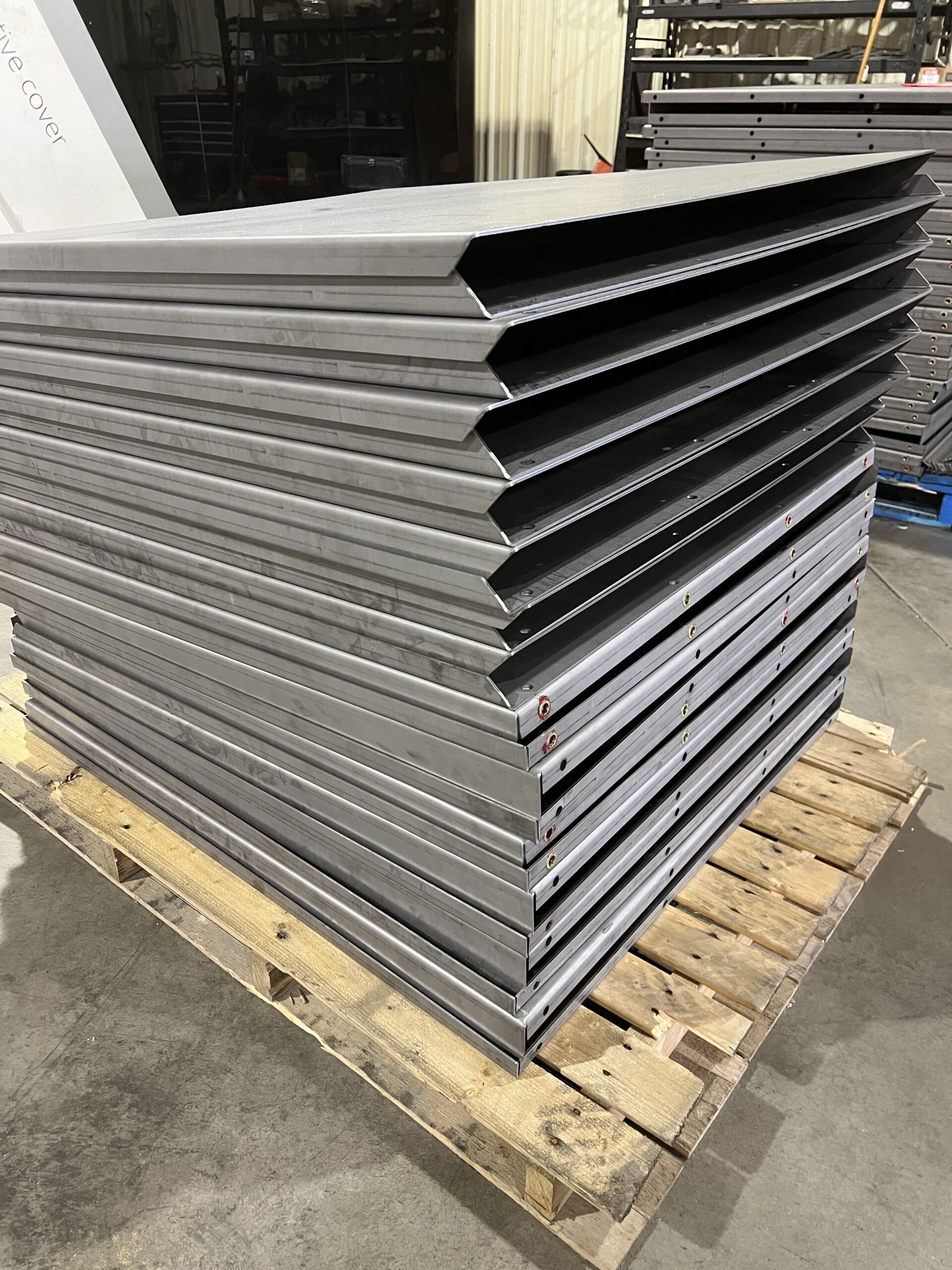

At Huxley Design, quality is at the core of everything we do. Our press brake operators don’t just operate the machines – they also ensure that the finished product is up to our high standards. Every bend, cut, and form is carefully checked to make sure it aligns with our strict quality guidelines.

We focus on minimizing errors and maximizing efficiency, which results in a finished product that meets our client’s expectations every time.

Here’s how we ensure that the quality of our metal fabrication, including the work of our brake press operators, is second to none:

1. Precise Planning and Setup

Before our brake press operators even begin their work, we take the time to thoroughly plan out every detail. This includes choosing the right material, understanding the specific needs of the project, and setting up our machines to achieve the precise bends and shapes required. Proper setup is essential to avoid errors and ensure that each piece is fabricated exactly as needed.

- Detailed Project Briefs: We start with clear plans based on our clients’ exact specifications.

- Machine Calibration: Every piece of equipment is calibrated before use, ensuring precision from the start.

2. Experienced Press Brake Operators

Our brake press operators bring years of experience to each job. They are experts at understanding the intricacies of different materials and knowing how to handle each one to ensure the best outcome. They carefully monitor every step of the process, checking for accuracy at each bend and ensuring that the metal is formed perfectly.

- Skilled Operators: Our operators have the knowledge and hands-on experience to deliver top-tier results.

- Attention to Detail: They maintain focus throughout the entire fabrication process, making sure every detail is spot-on.

3. Continuous Quality Control

Quality control is built into every step of our process. Once a part is fabricated, it undergoes a thorough inspection to ensure that it meets our standards and the client’s requirements.

We check for factors like the accuracy of bends, dimensions, and overall finish. If any part doesn’t meet our high standards, it’s corrected before moving on.

- Ongoing Checks: After each stage, we inspect for accuracy and consistency.

- Problem Resolution: Any issues are promptly addressed, so there’s no compromise in the final product.

4. Use of Advanced Technology

Technology plays a crucial role in maintaining quality at Huxley Design. Our brake press machines are equipped with advanced features that provide real-time feedback on the accuracy of each bend. This helps us adjust on the fly and ensure that each piece is consistently shaped according to specifications.

- Real-Time Monitoring: Our equipment allows for continuous monitoring of each bend.

- Adjustments as Needed: If something doesn’t align perfectly, adjustments can be made quickly, preventing errors from carrying forward.

5. Client Collaboration and Feedback

We believe that quality isn’t just about what happens in the shop – it’s also about ensuring that our clients are satisfied with the final result. We maintain an open line of communication throughout the entire project. By collaborating closely with our clients, we can address any changes or concerns in real time, ensuring the final product exceeds expectations.

- Client Engagement: We actively engage with our clients to ensure we’re meeting their needs.

- Iterative Feedback: If adjustments are needed, we work with the client to get it right.

6. Commitment to Continuous Improvement

At Huxley Design, we are always looking for ways to improve. We constantly evaluate our processes, machinery, and techniques to ensure we are delivering the best results possible. This commitment to continuous improvement helps us stay ahead of the curve in the metal fabrication industry and ensures that our brake press operators are always equipped to perform at their best.

- Ongoing Training: Our team participates in regular training to stay current with industry standards.

- Process Review: We regularly review our procedures to improve efficiency and quality.

FAQs about Brake Press Operator

What is a brake press operator?

A brake press operator is a skilled tradesperson. They use a press brake machine to bend sheet metal into various shapes. They follow blueprints, select tooling, and ensure the final product meets specifications.

Is being a press brake operator a good job?

A press brake operator position often provides stable manufacturing employment. The work requires attention to detail and can be physically demanding.

Pay varies by skill level, experience, and location. This career offers the chance to work with advanced machinery and specialize in different materials and thicknesses.

Is a press brake hard to operate?

Operating a press brake requires an understanding of the manufacturing process and training. Skilled operators often develop expertise through experience at companies specializing in CNC machining and sheet metal fabrication.

What is the job description of a brake press operator?

A brake press operator sets up and operates press brakes. They bend and form sheet metal into specific parts. They also adhere to safety protocols and conduct quality and security checks.

Where can I find a brake press operator near me?

At Huxley Design, we pride ourselves on our skilled team of brake press operators who are experienced in precision metal fabrication. If you’re looking for professional brake press operators near you, we encourage you to contact us directly. We offer both local and remote solutions and are happy to discuss how we can meet your fabrication needs, no matter where you’re located.

What qualifications do brake press operators have?

Our brake press operators are highly skilled individuals with a strong understanding of metal fabrication processes. They are trained to handle a variety of machines and materials with precision. Most of our operators have completed extensive on-the-job training and certifications that ensure they are equipped to meet high-quality standards.

What industries benefit from brake press operators and metal fabrication?

Brake press operators are essential in many industries, including construction, automotive, aerospace, and manufacturing. Huxley Design works across various sectors, providing precision metal components that meet the specific needs of each industry.

Can I hire a brake press operator for my own business?

If you’re looking to hire a brake press operator for your business, we can help connect you with trained professionals. Huxley Design offers both subcontracted and in-house training services to ensure your team is up to speed with the latest techniques and technology in metal fabrication.

What is the future of brake press operators with automation?

Automation is transforming many industries, including metal fabrication. At Huxley Design, we embrace the integration of automation alongside skilled brake press operators. While automated systems help streamline the process, our operators continue to play a vital role in ensuring precision and quality throughout production.

Conclusion

In the world of metal fabrication, brake press operators are the backbone of precision and efficiency. Their expertise in shaping metal into functional, high-quality components is essential for countless industries, from automotive to construction. As we’ve seen, these professionals need a strong combination of technical skills, attention to detail, and extensive training to ensure that every piece of metal is bent to perfection.

At Huxley Design, we understand the importance of skilled brake press operators. Our team is equipped with cutting-edge technology and years of experience to deliver top-notch metal fabrication services. We take pride in our commitment to quality, precision, and customer satisfaction.

Ready to bring your project to life with precision and quality? Contact us today to discuss how our expert brake press operators can help meet your fabrication needs.

Recent Comments